A Step-by-Step Guide to Preparing for an NDT Inspection

Pr

Understanding NDT Inspection

Non-Destructive Testing (NDT) is a crucial process in various industries, ensuring the integrity and safety of materials and structures without causing damage. Preparing for an NDT inspection involves several steps that ensure accurate and reliable results. Whether you are a seasoned professional or new to the field, understanding these steps can significantly enhance the inspection process.

Step 1: Define the Scope

Before initiating an NDT inspection, it's imperative to define the scope clearly. Determine what needs to be inspected, the type of materials involved, and the specific NDT methods to be used. Popular methods include ultrasonic testing, radiographic testing, and magnetic particle testing. Each method has its own advantages and is suitable for different types of materials and defects.

Step 2: Gather Necessary Documentation

Documentation is a key part of preparing for an NDT inspection. This includes previous inspection reports, blueprints, material specifications, and any relevant compliance standards. Having all necessary documents on hand will help in planning the inspection and ensure that all requirements are met.

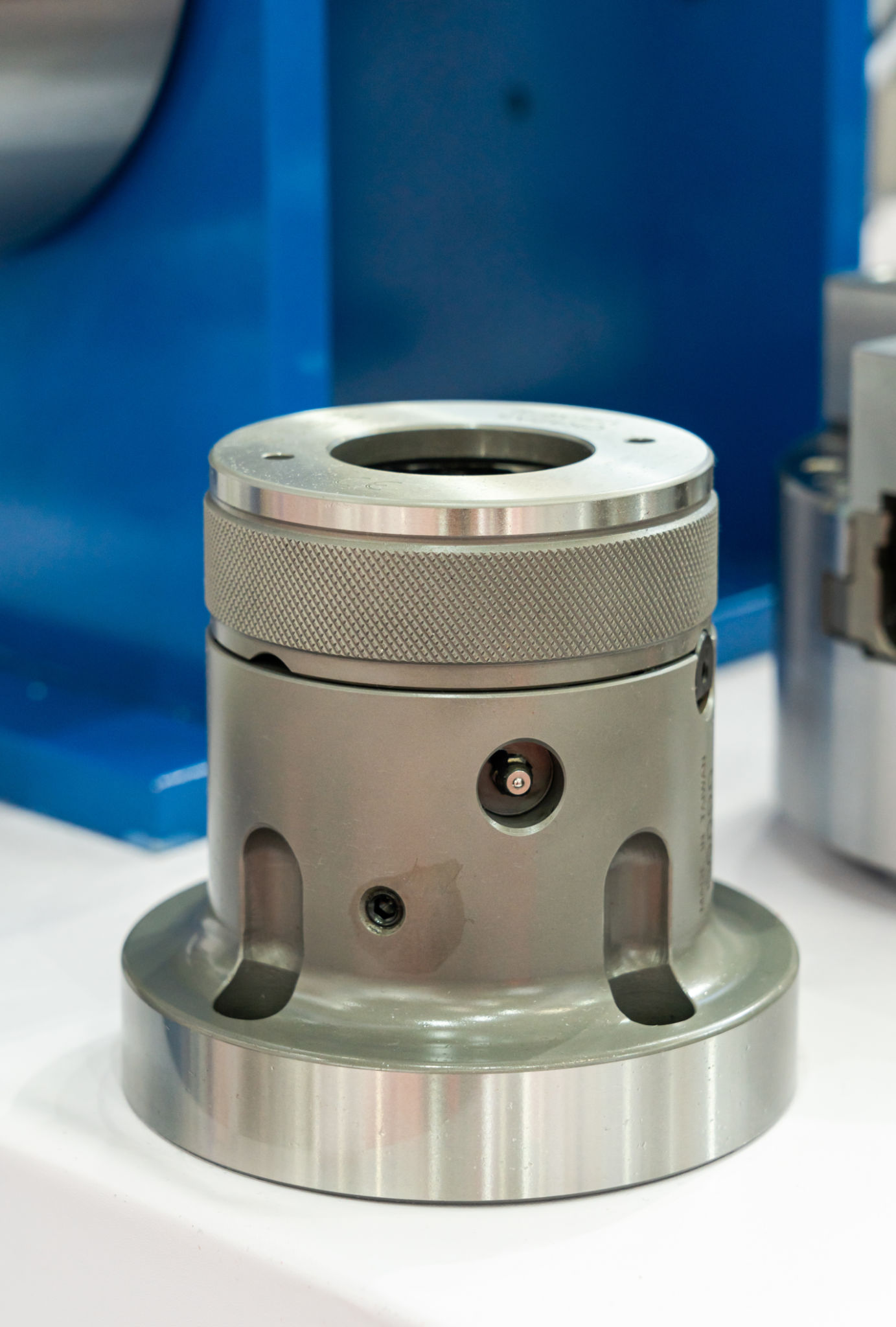

Step 3: Equipment Preparation

Ensuring that all inspection equipment is calibrated and functioning correctly is essential. Inspectors should perform routine checks on all tools and equipment to avoid any technical issues during the inspection. Additionally, having spare parts and backup equipment readily available can prevent delays.

Step 4: Site Preparation and Safety

Before the inspection begins, the site should be thoroughly prepared. This includes cleaning the area and ensuring that there are no obstructions that could interfere with the inspection process. Safety protocols must also be established to protect both inspectors and equipment. Proper lighting and environmental controls should be considered to maintain optimal inspection conditions.

Step 5: Conducting a Pre-Inspection Meeting

A pre-inspection meeting with all stakeholders is beneficial for discussing the inspection plan, clarifying roles, and addressing any concerns. This meeting should cover the sequence of operations, safety measures, and any site-specific procedures. Clear communication at this stage can greatly improve the efficiency of the inspection process.

Step 6: Execution of Inspection

During the actual inspection, follow the prepared plan meticulously. Inspectors should document findings comprehensively, noting any irregularities or areas of concern. Utilizing checklists can help ensure that no parts of the inspection are overlooked. Consistency and attention to detail are crucial for obtaining accurate results.

Step 7: Review and Report Findings

After completing the inspection, it's time to review all collected data and compile a detailed report. This report should highlight any defects found, their potential impact, and recommended corrective actions. Accurate reporting is vital for decision-making processes related to maintenance or repairs.

Step 8: Follow-Up Actions

The final step involves implementing any necessary corrective actions based on the inspection findings. This could include repairs, additional inspections, or adjustments to maintenance schedules. Regular follow-up ensures that issues identified during the NDT inspection are addressed promptly to maintain safety and integrity.

By following these steps, companies can ensure that their NDT inspections are thorough, efficient, and effective in maintaining safety standards across their operations.